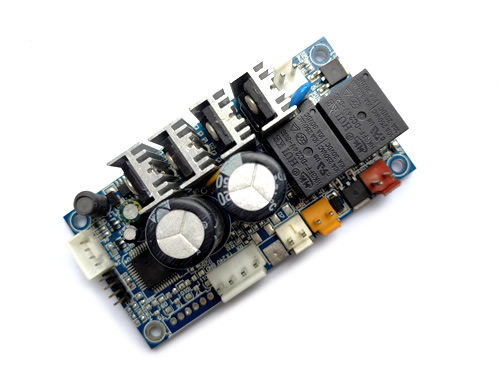

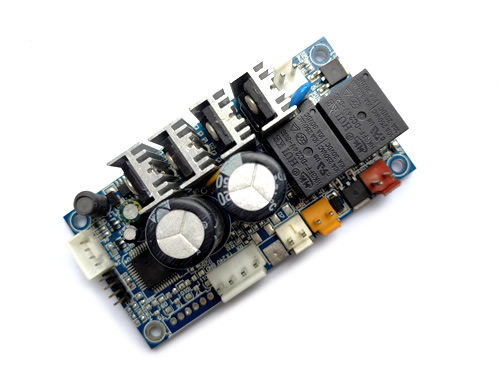

How can massage PCBA board manufacturers improve product quality

Release time: 2025/9/26 Source: Hongchuangda Electronic Technology

Quality improvement is the core of organizational management, and every enterprise is striving to do quality work, manufacturing related processes and control methods. Manufacturing enterprise managers are constantly striving for quality assurance and improvement. However, what can Dongguan PCBA manufacturers do to improve product quality? Establishing a quality management system is the core of quality management in manufacturing enterprises.

Why do PCBA manufacturers need to establish a quality management system? Why set up various inspection tests? Why do we need to do statistics and process control? At the end of the day, it' s all about preventing negative outcomes.

And why does negativity arise?

Through long-term production experience, it has been proven that quality problems in the manufacturing of all massager PCBA board products are caused by human factors. Therefore, a point is drawn that if they cannot be produced, it must be caused by someone. People make mistakes, which can lead to various defects. So, the core of quality management is prevention.

To prevent human error, it is necessary to establish a process framework and constrain it through systems, standards, and procedures. How to constrain it? It is about regulating and optimizing the behavior of each and every one of us. Let standards become habits, let habits become living standards. As a quality management personnel? We need to know our work priorities. Our focus is on supervising whether there is compliance with regulations, standards, and procedures, and strictly enforcing customer quality standards for products.

Quality management personnel must have a global perspective and a sense of serving customers. A good quality management system requires strict implementation and execution. If you are busy all day and fail to truly improve product quality, then you need to reflect on your work.

Why do PCBA manufacturers need to establish a quality management system? Why set up various inspection tests? Why do we need to do statistics and process control? At the end of the day, it' s all about preventing negative outcomes.

And why does negativity arise?

Through long-term production experience, it has been proven that quality problems in the manufacturing of all massager PCBA board products are caused by human factors. Therefore, a point is drawn that if they cannot be produced, it must be caused by someone. People make mistakes, which can lead to various defects. So, the core of quality management is prevention.

To prevent human error, it is necessary to establish a process framework and constrain it through systems, standards, and procedures. How to constrain it? It is about regulating and optimizing the behavior of each and every one of us. Let standards become habits, let habits become living standards. As a quality management personnel? We need to know our work priorities. Our focus is on supervising whether there is compliance with regulations, standards, and procedures, and strictly enforcing customer quality standards for products.

Quality management personnel must have a global perspective and a sense of serving customers. A good quality management system requires strict implementation and execution. If you are busy all day and fail to truly improve product quality, then you need to reflect on your work.