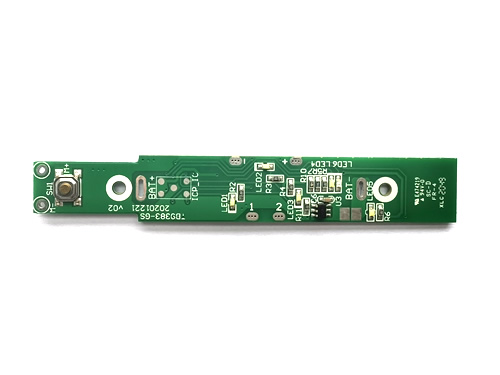

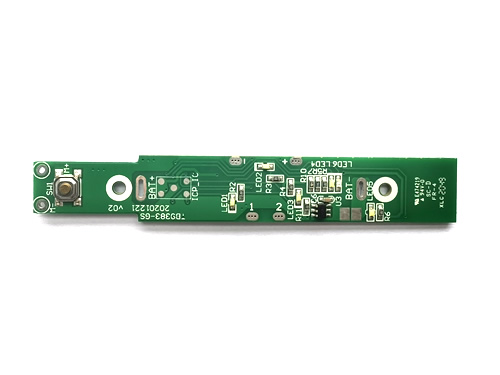

The core idea of lean production is implemented in the PCBA OEM factory for electric toothbrushes

Release time: 2025/9/26 Source: Hongchuangda Electronic Technology

In the daily management work of PCBA OEM factories, I always feel that the company has many problems and needs new changes, but I don' t know where to start. Although the company has PMC management, the production plan cannot be executed and implemented. If the salesperson says they are not in a hurry to ship, we immediately overturn the plan, wasting costs. There are regular inspections and records of production and manufacturing equipment, but accuracy is difficult to guarantee. Various document standards are only for the surface, made for the sake of doing, and even prepared for major customer audits. The various departments of Dongguan PCBA processing factory have difficulty communicating, shifting blame to each other, and employees are slack and dissatisfied. Although there is performance evaluation, it is not very effective. What should be done?

Learn a production management philosophy from Toyota' s lean production method, which is considered a management approach suitable for modern manufacturing enterprises. Although many companies want to implement lean management, they have not truly understood the core idea of lean production.

1. Lean production advocates removing all useless things, eliminating all waste, pursuing excellence, and streamlining all value-added work in product development, design, production, and management,

2. By emphasizing the role of people and adopting lean production methods, the production tasks and responsibility limits of electric toothbrush PCBA are transferred to workers who directly add value to the product. This empowers workers with autonomy in production and stimulates their interest and potential.

3. The goal of zero waste economic production is that inventory increases operating costs, conceals potential problems, advocates reducing inventory levels, and exposes the problems of the enterprise.

4. Continuous improvement, utilizing digital analysis to continuously improve production management methods, and relentlessly pursuing continuous improvement in product quality, cost, and service.

Learn a production management philosophy from Toyota' s lean production method, which is considered a management approach suitable for modern manufacturing enterprises. Although many companies want to implement lean management, they have not truly understood the core idea of lean production.

1. Lean production advocates removing all useless things, eliminating all waste, pursuing excellence, and streamlining all value-added work in product development, design, production, and management,

2. By emphasizing the role of people and adopting lean production methods, the production tasks and responsibility limits of electric toothbrush PCBA are transferred to workers who directly add value to the product. This empowers workers with autonomy in production and stimulates their interest and potential.

3. The goal of zero waste economic production is that inventory increases operating costs, conceals potential problems, advocates reducing inventory levels, and exposes the problems of the enterprise.

4. Continuous improvement, utilizing digital analysis to continuously improve production management methods, and relentlessly pursuing continuous improvement in product quality, cost, and service.