PCBA factory production efficiency improvement relies on these three points

Release time: 2025/9/26 Source: Hongchuangda Electronic Technology

In the operation of enterprises, cost reduction is a capability, and efficiency improvement is also a capability. Today, we will discuss with you the relevant experiences of manufacturing enterprises in terms of efficiency improvement. In manufacturing enterprises, the overall goal of factory management is always to improve efficiency, and the main factors that affect efficiency are the following three aspects:

1. Labor efficiency

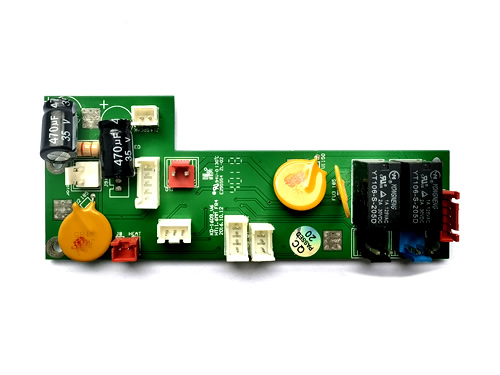

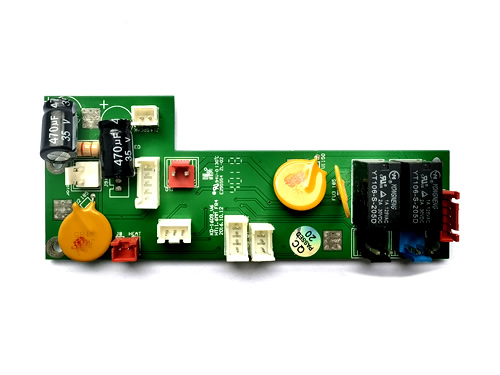

The labor efficiency of manufacturing enterprises is improved by processes, fixtures, equipment, and the skills and proficiency of employees, as well as the loyalty of employees to the company. Skilled workers are willing to work here, and many manufacturing enterprises often deduct their employees' piece rate wages and then reduce them. When profits are not high, employees are punished, which undermines their enthusiasm. In fact, improving the production efficiency of massager PCBA board processing enterprises relies on research and development capabilities, manufacturing equipment, and tooling process improvement, which requires a clear understanding.

2. Communication costs

Effective communication is actually a way for a company to improve its organizational efficiency, which is called establishing processes and systems, and then improving the execution of various departments in the company. Establish a collaborative approach among various departments in daily production to improve organizational operational efficiency and enhance the overall level of organizational operations. The PCBA processing project needs to be managed through meetings, such as weekly meetings, quarterly meetings, annual business meetings, quality meetings, and cost analysis meetings, which are integrated to improve the operational efficiency of the entire organization.

3. Team execution capability

In corporate culture, we need to establish the overall business goals of the enterprise, and at the same time, engage in cultural interaction to increase team cohesion. In fact, there are many potentials that can be stimulated when organizational managers are together. We must give the team a general goal, and the entire team should work together towards this goal in order to improve the performance concept of the entire team, so that everyone can come together and move forward together to achieve the goal of increasing efficiency.

Overall, cost reduction is a capability and efficiency improvement is a capability. Only by setting rules and regulations and organizing coordinated production with this goal can the operational level of PCBA factories be greatly improved.

1. Labor efficiency

The labor efficiency of manufacturing enterprises is improved by processes, fixtures, equipment, and the skills and proficiency of employees, as well as the loyalty of employees to the company. Skilled workers are willing to work here, and many manufacturing enterprises often deduct their employees' piece rate wages and then reduce them. When profits are not high, employees are punished, which undermines their enthusiasm. In fact, improving the production efficiency of massager PCBA board processing enterprises relies on research and development capabilities, manufacturing equipment, and tooling process improvement, which requires a clear understanding.

2. Communication costs

Effective communication is actually a way for a company to improve its organizational efficiency, which is called establishing processes and systems, and then improving the execution of various departments in the company. Establish a collaborative approach among various departments in daily production to improve organizational operational efficiency and enhance the overall level of organizational operations. The PCBA processing project needs to be managed through meetings, such as weekly meetings, quarterly meetings, annual business meetings, quality meetings, and cost analysis meetings, which are integrated to improve the operational efficiency of the entire organization.

3. Team execution capability

In corporate culture, we need to establish the overall business goals of the enterprise, and at the same time, engage in cultural interaction to increase team cohesion. In fact, there are many potentials that can be stimulated when organizational managers are together. We must give the team a general goal, and the entire team should work together towards this goal in order to improve the performance concept of the entire team, so that everyone can come together and move forward together to achieve the goal of increasing efficiency.

Overall, cost reduction is a capability and efficiency improvement is a capability. Only by setting rules and regulations and organizing coordinated production with this goal can the operational level of PCBA factories be greatly improved.