Three things must be done well for the successful construction of PCBA manufacturers digital factories

Release time: 2025/9/26 Source: Hongchuangda Electronic Technology

In recent years, more and more PCBA manufacturers have started digital transformation. During this process, bosses are very anxious, management is very frustrated, and employees are also exhausted. Is digitalization really that difficult? In fact, it is difficult for many companies to achieve success overnight. Most successful companies in digital transformation have spent several years laying the foundation. Therefore, the construction of a digital factory is a long-term process with its own development path and steps.

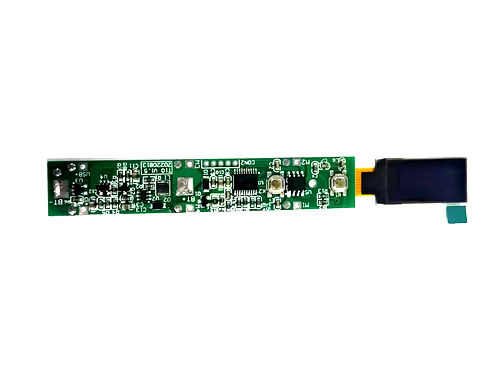

1. The refinement of management requires first establishing basic processes and doing a good job in refined management. This is not a coincidence. Without proper management, attempting to use a set of standardized software to constrain employee behavior will inevitably bring increasing costs of violating regulations to the PCBA board of electric toothbrushes.

2. Lean data. We often say that ERP relies on three parts software, seven parts implementation, and 12 parts data. Enterprises need to collect various types of data well. If they wait until the digital transformation to start collecting basic data, project costs and risks will increase because those software companies need to spend a lot of time collecting data first, and erroneous or missing data will make the project difficult to sustain.

3. Standardization of components. If enterprises want to digitize their factories, we first need to standardize and universalize the components, and do a good job in it. We should try to unify the components of similar products with different specifications or similar structures, so that they can be exchanged and replaced.

1. The refinement of management requires first establishing basic processes and doing a good job in refined management. This is not a coincidence. Without proper management, attempting to use a set of standardized software to constrain employee behavior will inevitably bring increasing costs of violating regulations to the PCBA board of electric toothbrushes.

2. Lean data. We often say that ERP relies on three parts software, seven parts implementation, and 12 parts data. Enterprises need to collect various types of data well. If they wait until the digital transformation to start collecting basic data, project costs and risks will increase because those software companies need to spend a lot of time collecting data first, and erroneous or missing data will make the project difficult to sustain.

3. Standardization of components. If enterprises want to digitize their factories, we first need to standardize and universalize the components, and do a good job in it. We should try to unify the components of similar products with different specifications or similar structures, so that they can be exchanged and replaced.