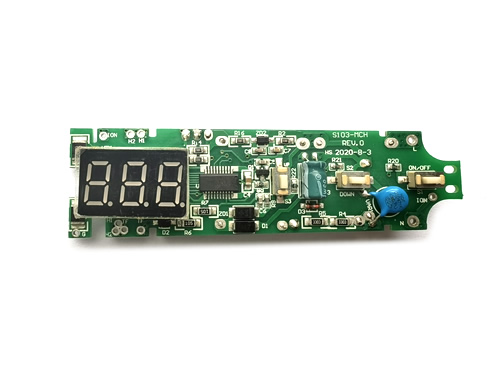

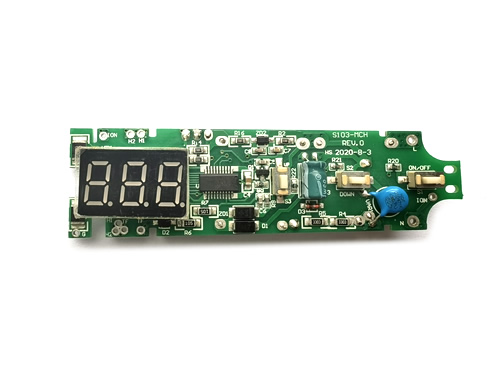

Ideas and methods for reducing labor costs in the operation of electric toothbrush PCBA board factories

Release time: 2025/9/26 Source: Hongchuangda Electronic Technology

How to reduce labor costs in the operation and management of electric toothbrush PCBA board factories? A well managed enterprise should achieve a state where employee compensation and benefits continue to improve and increase, while the overall labor cost of the enterprise continues to decrease. How can we achieve this benign state? Today, I will share relevant experiences with everyone.

Before obtaining good management methods, we must have an understanding of the business data of the enterprise. We can identify problems through data statistics and find corresponding solutions. Electric toothbrush PCBA board factories need to do well in the following three aspects of data statistics:

1. Statistically calculate the labor output ratio of each unit.

2. Statistically measure the per capita efficiency of each unit.

3. Statistically calculate the wage output ratio of non direct value creators.

Using these four methods to reduce labor costs for businesses based on statistical data:

1. Improve production efficiency

It is necessary for processing and manufacturing enterprises to make efforts in this regard. Only when production efficiency is improved can the unit price of enterprise products be competitive and customers can have long-term cooperation.

2. Improve the work efficiency of functional departments

In arranging production and planning, the efficiency of indirect departments can also affect overall efficiency, such as whether materials are purchased in a timely manner, which will affect production scheduling and delivery time.

3. Reduce costs and increase efficiency through product design and process optimization

In production and manufacturing, we need to improve the PCBA board of our electric toothbrush with new processes and adopt new technologies to increase the manufacturing efficiency and production costs of our products, thereby increasing the overall profit of product manufacturing.

4. Carry out automation and intelligent transformation.

In today' s era of automation development, manufacturing enterprises must rely on the power of technology to improve their production efficiency, reduce manual dependence in the production process, and greatly increase production capacity. For PCBA manufacturers, the main approach is to introduce advanced robotic arms to replace manual production.

Before obtaining good management methods, we must have an understanding of the business data of the enterprise. We can identify problems through data statistics and find corresponding solutions. Electric toothbrush PCBA board factories need to do well in the following three aspects of data statistics:

1. Statistically calculate the labor output ratio of each unit.

2. Statistically measure the per capita efficiency of each unit.

3. Statistically calculate the wage output ratio of non direct value creators.

Using these four methods to reduce labor costs for businesses based on statistical data:

1. Improve production efficiency

It is necessary for processing and manufacturing enterprises to make efforts in this regard. Only when production efficiency is improved can the unit price of enterprise products be competitive and customers can have long-term cooperation.

2. Improve the work efficiency of functional departments

In arranging production and planning, the efficiency of indirect departments can also affect overall efficiency, such as whether materials are purchased in a timely manner, which will affect production scheduling and delivery time.

3. Reduce costs and increase efficiency through product design and process optimization

In production and manufacturing, we need to improve the PCBA board of our electric toothbrush with new processes and adopt new technologies to increase the manufacturing efficiency and production costs of our products, thereby increasing the overall profit of product manufacturing.

4. Carry out automation and intelligent transformation.

In today' s era of automation development, manufacturing enterprises must rely on the power of technology to improve their production efficiency, reduce manual dependence in the production process, and greatly increase production capacity. For PCBA manufacturers, the main approach is to introduce advanced robotic arms to replace manual production.