How can the PCBA control board factory for electric toothbrushes achieve digital transformation in production?

Release time: 2025/9/26 Source: Hongchuangda Electronic Technology

How can manufacturing enterprises improve the internal management level of their factories, ensure compliance with the audit requirements of major customers, and achieve efficient operations through data-driven and intelligent leadership concepts. We need to follow Huawei' s supplier quality management strategy based on the principles of three modernizations and strict entry and exit, including three modernizations and IT management, production automation, and personnel specialization.

1. IQC Incoming Inspection Opinion is mainly used to display key indicators of incoming inspection in real time, such as completion rate, qualification rate, analysis of defective suppliers, and some trend charts, in order to monitor material quality and handle abnormal situations in a timely manner.

2. The IPQC semi-finished product inspection dashboard mainly tracks the quality performance of semi-finished products, such as pass rate, one-time pass rate, trend anomaly handling time, and the proportion of non conformities caused by equipment and materials.

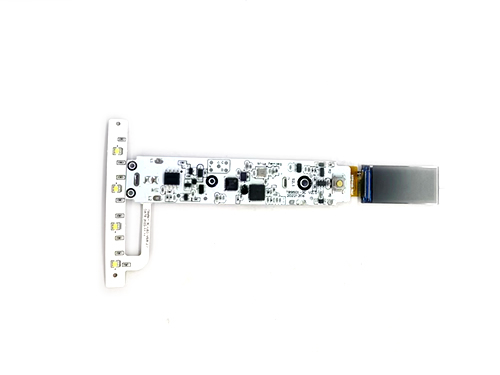

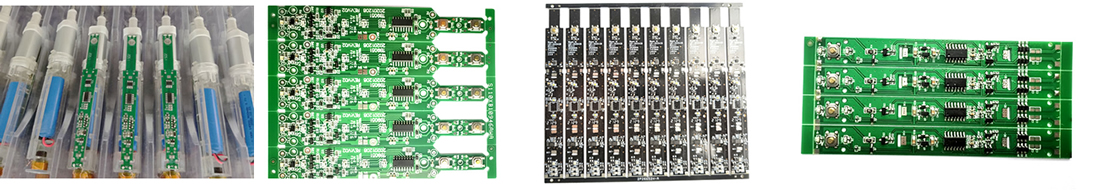

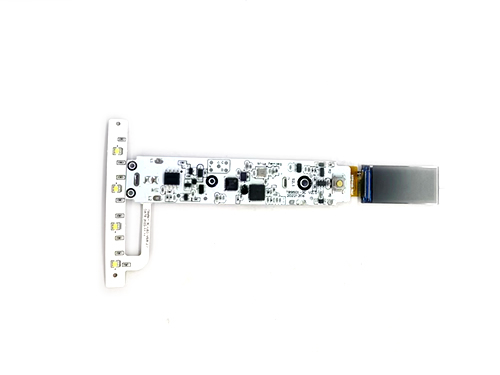

Electric toothbrush PCBA control board

3. FQC finished product inspection board. Mainly focusing on the quality of finished products, providing trend charts of daily and historical inspection pass rates, as well as a trend of current month or defective materials and their processing time.

4. OQC shipment inspection dashboard records the status of daily shipment and stocking, calculates the completion rate of stocking, inspection qualification rate, and shipment completion rate, and displays the monthly shipment completion rate trend.

5. The quality anomaly dashboard mainly displays various types of inspection anomaly orders that have not been processed for the current day or month in a rolling manner, used to promote rapid response and closed-loop resolution of problems.

6. Main production process indicators dashboard. Display the key performance indicators of the main processes of the PCBA control board for electric toothbrushes in the form of charts, such as the daily and monthly trends of output rate, one-time pass rate, and monthly changes in output.

7. Inventory dashboard, real-time updates of raw material, semi-finished product, and finished product inventory amounts and proportions, comparing and displaying monthly changes in inventory at each stage.

8. Equipment signage. Mainly used to monitor the maintenance status of equipment, including daily maintenance quantity and completion rate, analyze equipment downtime due to faults, average response time for maintenance, trend of repeated repairs, and daily maintenance completion rate.

Overall, the digital solution for factory management mainly relies on online methods, including mass ERP system and benchmarking, to establish a three-level performance indicator system. We distinguish between management and execution levels, and another aspect is visualization, which mainly provides Dongguan PCBA manufacturer managers with a comprehensive view through three dimensions, clearly and comprehensively reflecting the company' s operational status from raw material receipt to finished product shipment, thereby improving decision-making efficiency, ensuring product quality, reducing operating costs, and effectively responding to market challenges.

How can Dongguan PCBA manufacturers use digital means to control and optimize their production processes?

1. IQC Incoming Inspection Opinion is mainly used to display key indicators of incoming inspection in real time, such as completion rate, qualification rate, analysis of defective suppliers, and some trend charts, in order to monitor material quality and handle abnormal situations in a timely manner.

2. The IPQC semi-finished product inspection dashboard mainly tracks the quality performance of semi-finished products, such as pass rate, one-time pass rate, trend anomaly handling time, and the proportion of non conformities caused by equipment and materials.

Electric toothbrush PCBA control board

3. FQC finished product inspection board. Mainly focusing on the quality of finished products, providing trend charts of daily and historical inspection pass rates, as well as a trend of current month or defective materials and their processing time.

4. OQC shipment inspection dashboard records the status of daily shipment and stocking, calculates the completion rate of stocking, inspection qualification rate, and shipment completion rate, and displays the monthly shipment completion rate trend.

5. The quality anomaly dashboard mainly displays various types of inspection anomaly orders that have not been processed for the current day or month in a rolling manner, used to promote rapid response and closed-loop resolution of problems.

6. Main production process indicators dashboard. Display the key performance indicators of the main processes of the PCBA control board for electric toothbrushes in the form of charts, such as the daily and monthly trends of output rate, one-time pass rate, and monthly changes in output.

7. Inventory dashboard, real-time updates of raw material, semi-finished product, and finished product inventory amounts and proportions, comparing and displaying monthly changes in inventory at each stage.

8. Equipment signage. Mainly used to monitor the maintenance status of equipment, including daily maintenance quantity and completion rate, analyze equipment downtime due to faults, average response time for maintenance, trend of repeated repairs, and daily maintenance completion rate.

Overall, the digital solution for factory management mainly relies on online methods, including mass ERP system and benchmarking, to establish a three-level performance indicator system. We distinguish between management and execution levels, and another aspect is visualization, which mainly provides Dongguan PCBA manufacturer managers with a comprehensive view through three dimensions, clearly and comprehensively reflecting the company' s operational status from raw material receipt to finished product shipment, thereby improving decision-making efficiency, ensuring product quality, reducing operating costs, and effectively responding to market challenges.